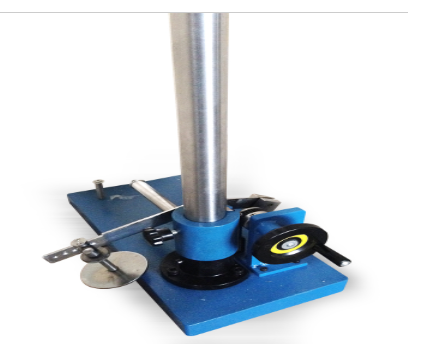

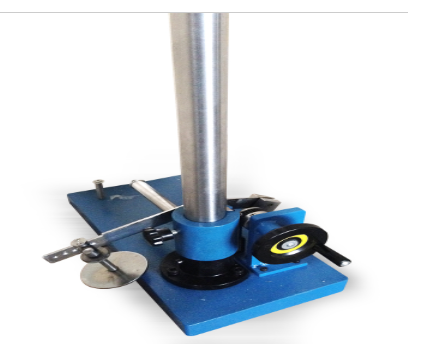

I. Product Overview

これFleece Loop Length Tester is a specialized instrument designed to measure the fiber loop length distribution in fleece fabrics, critical for evaluating softness, bulkiness, and durability. It utilizes non-contact laser scanning technology to ensure precise and repeatable measurements aligned with international textile standards.

- Type: Automated fiber analysis system

- Measurement Range: 10–1000 μm (loop length) | 0.1–50mm²/s (fiber density)

- Sample Type: Knitted fleece, woven pile fabrics, artificial fur

- Key Metrics:

- Loop length average (μm)

- Fiber density (fibers/cm²)

- Loop uniformity coefficient (CU)

II. Technical Specifications

| パラメータ |

仕様 |

| Measurement Principle |

Laser micrometer + AI pattern recognition |

| に決心させる |

±0.5 μm (ISO 137 standard validation) |

| ひょうほんりょう |

100×100mm (adjustable clamping frame) |

| Scanning Speed |

300 mm/s (full-area mapping) |

| 電源装置 |

220V/50Hz, 0.8kW |

| 寸法すんぽう |

500×400×700mm (W×D×H) |

III. Key Features

- Dual Measurement Modes:

- Static Mode: Fixed sample analysis

- Dynamic Mode: Simulates stretching/compression

- Advanced Analysis:

- 3D loop structure visualization

- Real-time histogram distribution

- Batch data comparison (Excel/PDF export)

- Automation:

- Auto-focus laser calibration

- Anti-drift sensor system

- Self-cleaning optical lens

IV. Compliance Standards

- ISO 137 (Textile fiber length and fineness)

- ASTM D1414 (Fiber length in flocking fabrics)

- AATCC 20A (Fiber analysis methodology)

- GB/T 14335 (Chinese fiber length standard)

V. Applications

- Quality Control: Monitoring fleece fabric uniformity

- R&D: Developing high-loft insulation materials

- Forensic Analysis: Evaluating wear-induced fiber damage

- Textile Education: Training on fiber structure analysis

Standard Operation Workflow:

- Sample Mounting: Secure fabric on vacuum table

- Parameter Setup: Select test mode (static/dynamic)

- Scanning: Full-area fiber mapping (2–10 minutes)

- Analysis: Generate loop length distribution curves

- Reporting: Export compliance-ready data

Safety Precautions:

- Avoid direct eye exposure to laser beams

- Use grounded power supply only

- Clean optical components with isopropyl alcohol

免責事項: 上記のコンテンツは,業界内部者のみの参照およびコミュニケーションのためであり,その正確性または完全性を保証しません.関連法規および本ウェブサイトの規制により,関連品を購入するユニットまたは個人は,有効な資格および資格条件を取得する必要があります.