Combines five-finger/burger/plastic scraping; tests automotive interiors (plastics, rubber, leather)

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

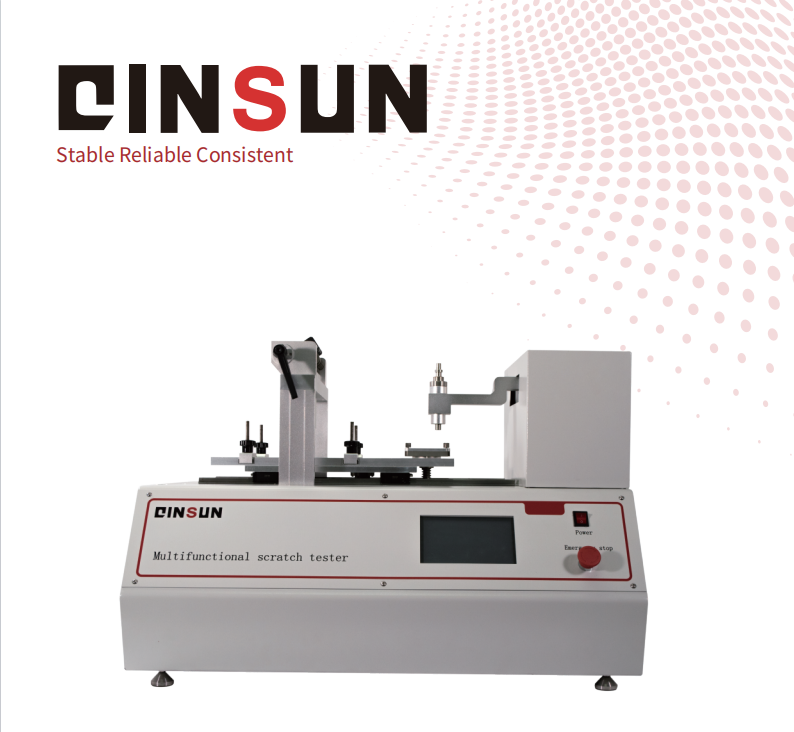

The Multi-Functional Scratch Tester suits automotive interior materials like plastics, rubber, leather, etc., for scratch resistance testing. It integrates common methods in the automotive industry. With an LCD screen for control, users can freely set test parameters. High-quality stepping motors and guide rail structures ensure high precision, good repeatability, and long service life.

It is suitable for testing automotive interior materials, plastics, rubber, leather, coated fabrics, coating materials, composite materials, paints, inks, soft metals and other industries. It is widely used in product quality control, new product development performance verification, testing mechanism testing and other fields.

It is applicable to the performance verification of new products, quality control of the production department, and the of material properties for the third-party testing organization, the product performance verification laboratory, and the quality and technical supervisiondepartment, etc.

PV 3952 Plastic interior parts scratch resistance test

Ford BN 108-03. 13 Scratch resistance test

BMW 0180. PA-P 028 Scratch resistance test (cross-cut method)

BMW GS 97034-9. PA 0015 Scratch resistance test

ADAF KEUR 00824-402 Scratch resistance test

GME 60401 Scratch resistance test (cross-cut method)

GM 14829 Scratch resistance test (cross-cut method)

Jaguar-Landrover TPJLR.52.004 Scratch resistance test

GM N 3943 Plastic scratch and scratch test - Five-finger test

LP 463DD-18-01 Scratch and abrasion resistance test - Five-finger test

GMW 14130.14688 Scratch resistance test

8350Z-SDA-9000 Scratch resistance test

NES M M0159 Polypropylene interior parts scratch resistance test

1. The apparatus consists of the drive motor mechanism, scraping component, the sample holder fixing devices and other components.

2. The scraper assembly includes a bracket scratch; scraping means scrape the specified bit sets, pressurizing means (weights and weight support bar) and the like.

3. Free installation, replacement and removal of different specifications, scraping means can be implemented in a uniform way linear motion scraping under different loads.

4. The use of embedded systems, man-machine interface for automated control of the testing process, using precision servo motor, ball screw driver for the scraping speed standards under the control accuracy with a decisive role.

5. The use of tungsten carbide makes scraping means, increase the instrument pot life.

6. The use of aluminum and stainless steel, simple appearance, lightweight and corrosion resistant.

Test mode: automation | Scraper head lift: pneumatic |

Test speed: 10-200mm/s | Control screen: intelligent touch |

Number of scratches: it can be freely set | Working station: single station |

Scratch head size: it can be interchanged | Appearance size: 8400mm*5400mm*700mm |

Weight: 95Kg | Power: 220V |

The accessories of a multi-functional scraper mainly include the scraping assembly, pressure device, sample clamping and fixing device, and drive mechanism. The following are detailed descriptions:

Scraping Assembly: This includes the scraping bracket, scraping fingers, and scraping finger positioning sleeve. Scraping fingers are made of various materials, such as tungsten carbide (used for metal scraping heads to increase instrument lifespan) and polymethyl methacrylate (PMMA, used for plastic scraping fingers, 16mm diameter, 1mm thickness, 0.5mm edge radius, Shore D85 hardness). Metal scraping heads are available in various diameters such as 0.5mm, 0.75mm, 1mm (Erichsen 318), 3mm, 5mm, and 7mm to meet different testing needs.

Pressure Device: This typically consists of weights and a weight support rod. The total weight of the pressure weights and scraping assembly can be selected arbitrarily, such as 2N, 3N, 5N, 7N, 8N, 10N, 12N, 15N, and 20N, with a mass error not exceeding 1%, ensuring uniform unidirectional linear scraping motion under different loads.

Sample clamping and fixing device: Used to fix the sample in place, ensuring its stable position during testing and preventing movement or deflection, thus guaranteeing the accuracy of the test results.

Drive mechanism: Driven by a motor, this mechanism propels the scraping component in a linear scraping motion across the sample surface. Some instruments employ precision servo motors and ball screw drives, which play a crucial role in the accuracy of scraping speed control under relevant standards.

The main steps for using the multi-functional scratch resistance tester are as follows:

I. Preparation

Prepare accessories and test samples:

Prepare all accessories for the T109 multi-functional scratch resistance tester (such as the scratch head, weights, connecting rod, etc.).

Prepare the sample to be tested, ensuring its surface is flat and free of impurities.

Select test method:

The T109 multi-functional scratch resistance tester supports five-finger scratching and cross-scraping methods. Select the appropriate test method according to your testing requirements.

II. Setting parameters and installing accessories

Setting parameters:

Turn on the device's display screen and set the parameters, including scratching speed, scratching distance, and number of scratches. These parameters should be adjusted according to specific testing requirements and sample characteristics.

Installing accessories:

Install the corresponding scratch head and weights according to the selected test method.

Install the scratch head at the bottom of the shaft and load the weights onto the top of the shaft.

Fix the test sample onto the testing platform and secure the connecting rod so that the scratch head can contact and scratch the sample surface.

III. Testing

Starting the Test:

After confirming that all settings and installation are correct, start the T109 multi-functional scratch resistance tester to conduct the test.

Observation and Recording:

During the test, observe and record the scratches left by the scratch head on the sample surface.

Microscopes or other tools can be used for more detailed observation, and the depth, width, and other parameters of the scratches can be recorded.

IV. Test Completion and Result Analysis

Stopping the Test:

Stop the test when the preset number of tests is reached or obvious scratches are observed.

Result Analysis:

Analyze and compare the test samples to evaluate the scratch performance and durability of the material surface.

The scratch resistance of the material can be evaluated based on parameters such as the depth and width of the scratches.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com