Hydrogen Meter is a specialized testing device independently designed and manufactur

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

The Hydrogen Meter is a specialized testing device independently designed and manufactured by our company for qualitative detection of hydrogen content in molten casting aluminum. Despite being an economical model, its simple operation and rapid testing capabilities make it the preferred choice for many experienced manufacturers.

動作原理

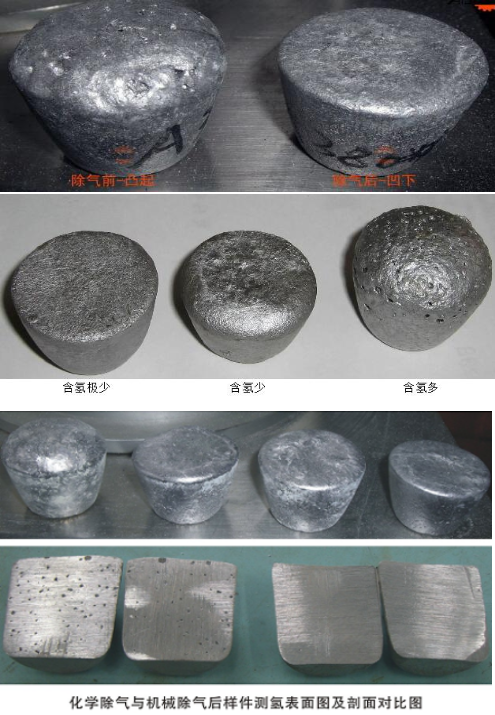

Based on the reduced pressure solidification method, the test sample solidifies under vacuum conditions. During this process, hydrogen dissolved in the molten aluminum gradually precipitates, forming bubbles inside or on the surface of the sample. The hydrogen content is evaluated by:

Key Features:

Sample Evaluation Methods

A. Surface Observation Method

B. Cross-Sectional Porosity Analysis

C. Aluminum Density Measurement

Technical Parameter

| パラメータ | 仕様 |

|---|---|

| Dimensions (L×W×H) mm | 600×500×1400 |

| Weight kg | 120 |

| Sample Weight g | 100 |

| Pumping Speed L/s | 2 |

| Vacuum Range (Adjustable) kPa | -100 to -1.3 |

| Ultimate Vacuum Time min | <4 seconds |

| Vacuum Pump Motor Power kW | 0.37 |

| Pinhole Grade | Number of Pinholes (per cm) | Pinhole Diameter (mm) | Percentage Distribution (%) |

|---|---|---|---|

| 1 | <5 | <0.1 | 90 |

| 1 | <5 | 0.1-0.2 | 10 |

| 2 | <10 | <0.1 | 80 |

| 2 | <10 | 0.1-0.2 | 20 |

| 3 | <15 | <0.3 | 80 |

| 3 | <15 | 0.3-0.5 | 20 |

| 4 | <20 | <0.5 | 70 |

| 4 | <20 | 0.5-1.0 | 30 |

| 5 | <25 | <0.5 | 60 |

| 5 | <25 | 0.5-1.0 | 30 |

| 5 | <25 | >1.0 | 10 |

免責事項: 上記のコンテンツは,業界内部者のみの参照およびコミュニケーションのためであり,その正確性または完全性を保証しません.関連法規および本ウェブサイトの規制により,関連品を購入するユニットまたは個人は,有効な資格および資格条件を取得する必要があります.

会社電話

+86-21-6420 0566

営業時間

月曜日から金曜日

携帯電話:

13816217984

メール:

info@qinsun-lab.com