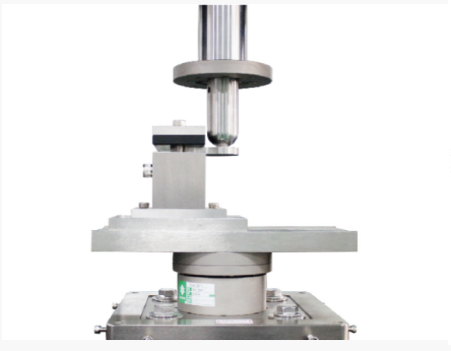

I. Main ApplicationsThe Tibial Tray Fatigue Testing Machine is primarily used to evaluate the f

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

Standard

| パラメータ | 仕様 |

|---|---|

| Max. Dynamic Force | ±3,000 N (6,000 N peak optional) |

| Frequency Range | 0.1–10 Hz (0.01 Hz increments) |

| Load Ratio (R) | 0.1–10 (adjustable) |

| Axial Displacement | ±20 mm (0.1 μm resolution) |

| Torque Capacity | ±20 Nm (0.01 Nm resolution) |

| おんどはんい | -20°C to +50°C (environmental chamber) |

| Humidity Control | 10–95% RH (non-condensing) |

| Data Sampling Rate | 100 kHz (synchronized across 16 channels) |

| Power Requirements | 220V/110V ±10%, 50/60Hz, 2,000W |

| Dimensions (W×D×H) | 1,500 × 1,000 × 2,000 mm |

| じゅうりょう | 750 kg (including environmental chamber) |

| Noise Level | <65 dB (A-weighted) |

免責事項: 上記のコンテンツは,業界内部者のみの参照およびコミュニケーションのためであり,その正確性または完全性を保証しません.関連法規および本ウェブサイトの規制により,関連品を購入するユニットまたは個人は,有効な資格および資格条件を取得する必要があります.

会社電話

+86-21-6420 0566

営業時間

月曜日から金曜日

携帯電話:

13816217984

メール:

info@qinsun-lab.com